Category

Disc-type Scaffolding

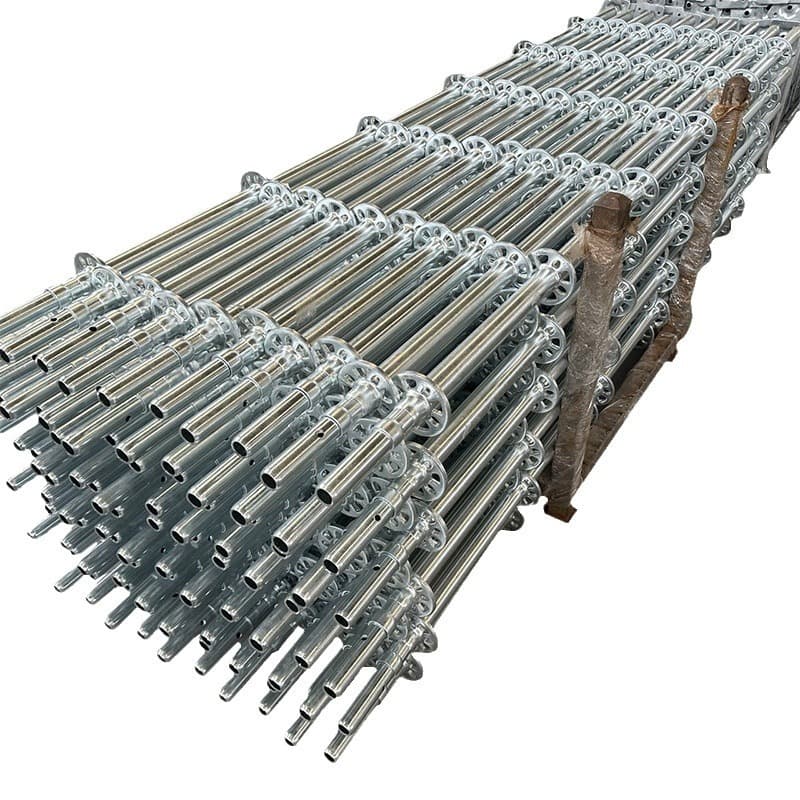

Disc-type scaffolding, also known as “disc-type scaffolding,” is a temporary support or work platform structure constructed primarily from hot-dip galvanized steel pipes. It is assembled using vertical poles with built-in “disc-type joints” and horizontal/diagonal poles with plugs. Its core innovation lies in the “disc-type joint design”—discs are welded to the vertical poles at regular intervals (usually 500mm). The end plugs of the horizontal and diagonal poles plug directly into the holes in the discs and are quickly locked with wedge pins, eliminating the need for additional fasteners and achieving a “plug-and-lock” assembly.

Compared to traditional fastener-type scaffolding, disc-type scaffolding offers significantly improved joint torsional stiffness and overall stability. Its highly standardized components accommodate support requirements of varying spans and heights, allowing for working heights exceeding 50 meters (higher heights can be customized for special projects).

Disc-type Scaffolding

1. Load-Bearing Support Frame (Mainly for Structural Support)

Core Features: High load-bearing capacity, close spacing between vertical posts (typically 0.6-1.2m). Vertical and horizontal post spacing is determined based on load calculations, and diagonal posts are arranged more closely (diagonal posts are required on each frame).

Load Rating: Based on the allowable load capacity of the vertical posts, they are classified as light (≤10kN), medium (10-20kN), and heavy (≥20kN). The heavy type is commonly used in heavy-load applications such as bridges and long-span slabs.

Applications: Support for concrete structure formwork (such as slabs, beams, and columns), bridge construction support, and temporary support for large equipment installation.

2. Working Scaffold (Mainly for Work)

Core Features: Emphasis on flexibility, wide spacing between vertical posts (1.2-2.4m), and diagonal posts are arranged "every other post" or "every two posts" to meet the load requirements of personnel and tools. Load requirements: Uniformly distributed load on the working floor ≤ 2.0 kN/㎡ (approximately 200 kg/㎡). Overloading of materials is strictly prohibited.

Applicable scenarios: Building exterior wall decoration, interior ceiling construction, steel structure factory maintenance, and overhead pipeline installation.