High Quality Galvanized Steel Flange Nuts Fasteners with Polished Finish for Automotive Mining &#...

Grade: 4.8, 8.8, 10.9, 12.9, Material: Q235, 35K, 45K, 40Cr, 35Crmo, 42Crmo, Surface Treatment: Blackened, Electrogalvanized, Dacromet, Hot-dip Galvanized, Galvanized, etc!

DIN 934 Refined Hexagonal Nut

Grade: 4.8, 8.8, 10.9, 12.9, Material: Q235, 35K, 45K, 40Cr, 35Crmo, 42Crmo, Surface Treatment: Blackened, Electrogalvanized, Dacromet, Hot-dip Galvanized, Galvanized, etc!

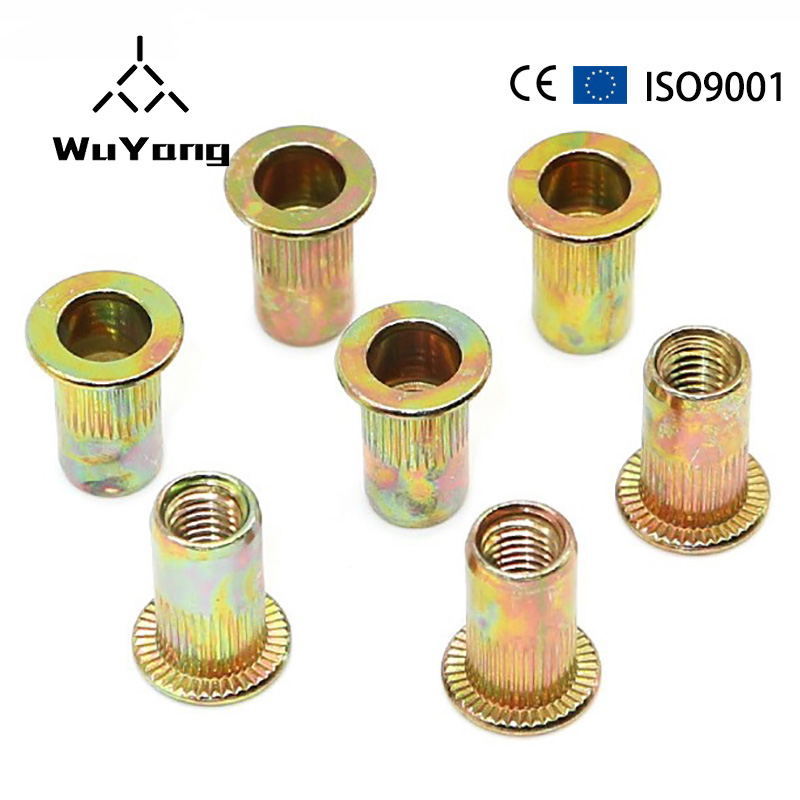

Refined rivet nuts

Rivet nuts GB/T17880 Grade: 4.8, 8.8, 10.9, 12.9, Material: Q235, 35K, 45K, 40Cr, 35Crmo, 42Crmo, Surface Treatment: Blackened, Electrogalvanized, Dacromet, Hot-dip Galvanized, Galvanized, etc!

M3 M4 M5 M6 M8 M10 M12 M14 M16 DIN6926 Stainless Steel 304 Nylock Nut Flange Nylon Insert Locking...

Flange anti loosening nut is a type of nut with special structure and performance. The following is a detailed introduction for you: characteristic: Flange design: There is a wider flange at the bottom of the nut, which not only increases the contact area between the nut and the connecting piece, reduces the pressure per unit area, thereby reducing damage to the surface of the connecting piece, but also helps to improve the bearing capacity and stability of the nut. Excellent anti loosening performance: Through various anti loosening mechanisms, such as adding special coatings on threads, using deformed threads, embedding elastic materials (such as nylon rings), etc., it can effectively resist loosening caused by factors such as vibration, impact, and temperature changes, ensuring the reliability and safety of the connection. High strength: usually made of high-strength materials, capable of withstanding large loads.

Round nutslotted locking nut

The advantages of fixing components on the shaft with round nuts: Capable of withstanding significant axial forces and easy to disassemble and assemble; Used for parts and bearings that are far away, it can avoid using long sleeves, which is beneficial for fixing the parts.