- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Disc-type Scaffolding

Disc-type scaffolding, also known as “disc-type scaffolding,” is a temporary support or work platform structure constructed primarily from hot-dip galvanized steel pipes. It is assembled using vertical poles with built-in “disc-type joints” and horizontal/diagonal poles with plugs. Its core innovation lies in the “disc-type joint design”—discs are welded to the vertical poles at regular intervals (usually 500mm). The end plugs of the horizontal and diagonal poles plug directly into the holes in the discs and are quickly locked with wedge pins, eliminating the need for additional fasteners and achieving a “plug-and-lock” assembly. Compared to traditional fastener-type scaffolding, disc-type scaffolding offers significantly improved joint torsional stiffness and overall stability. Its highly standardized components accommodate support requirements of varying spans and heights, allowing for working heights exceeding 50 meters (higher heights can be customized for special projects).

Scaffolding Fasteners

Scaffolding fasteners are the core connectors that connect scaffolding uprights, crossbars, sweeping rods and other components. Their quality and correct use directly determine the stability of the overall scaffolding structure and construction safety.

Aluminum Alloys Mobile Scaffolding with Steel Pipes

Mobile scaffolding, also known as “movable scaffolding,” is primarily constructed of steel pipes, aluminum alloys, and other materials. These components are assembled through connectors to create a stable frame structure. Equipped with universal or fixed wheels with brakes, these temporary work platforms can be moved on level ground. Mobile scaffolding provides a safe and stable platform for workers working at height, while also supporting loads such as tools and materials. Operating heights typically range from 2 to 15 meters (higher with custom designs). Unlike traditional fixed scaffolding (such as floor-standing or cantilever scaffolding), it eliminates the need for embedded anchors in the ground, simplifying installation and movement.

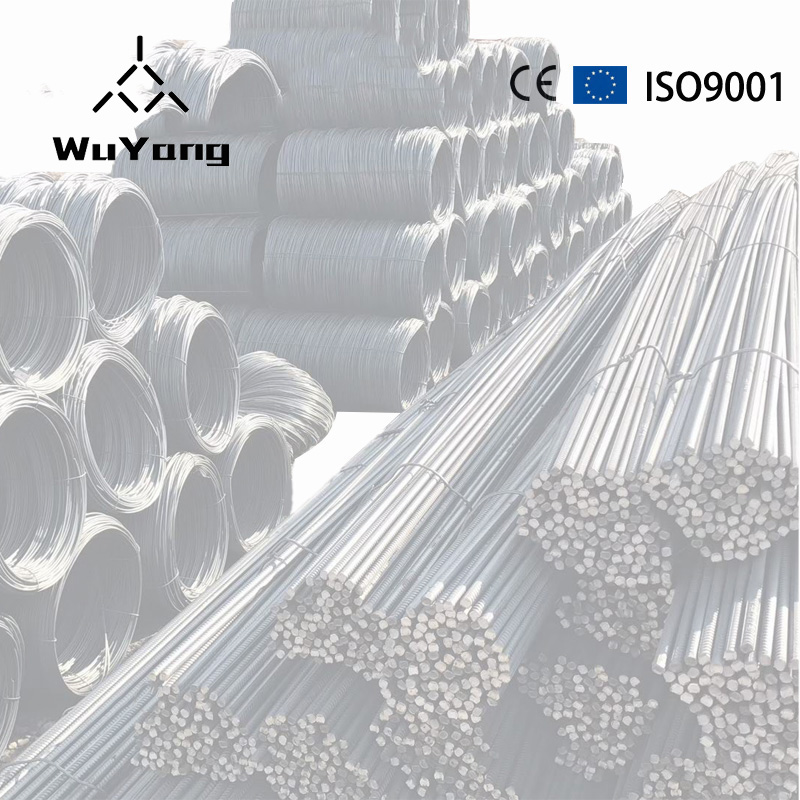

Wholesale of steel

The main function of steel is as a building material and industrial material, widely used in various structures and equipment manufacturing.

Engineering construction accessories and all types of products

Wuyang undertakes materials required for construction projects worldwide.Engineering accessories include various types to meet the needs of different engineering projects.

Cannon nail

There are various types of cannon nails, including ceiling nails, pipe clamp nails, fire studs, wooden keel nails, and hook nails. According to different calibers, gun studs are divided into large and mini models. The head diameter of the large gun stud is generally 8.3-8.5mm, while the head diameter of the mini gun stud is 7.2-7.3mm. In addition, ceiling nails can be divided into different specifications based on the model (screw hole), including 6 (M6), 8 (M8), and 10 (M10).

All types of photovoltaic accessories

Undertake the materials required for photovoltaic engineering construction from around the world.Choosing high-quality photovoltaic accessories is crucial.

All types of power fittings and accessories

With the advancement of power grid technology, the types and functions of power fittings are constantly expanding. Electric power fittings play an indispensable role in the power system, with various types and functions, playing an important role in ensuring the stable operation and safety of the power system.

All types of curtain wall accessories

The selection and use of curtain wall accessories directly affect the appearance, safety, and service life of buildings. Therefore, when selecting and using these accessories, it is necessary to strictly follow relevant building codes and standards to ensure their quality and safety.